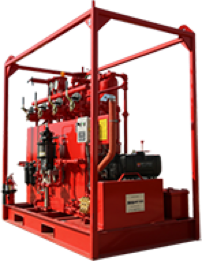

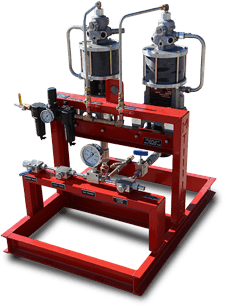

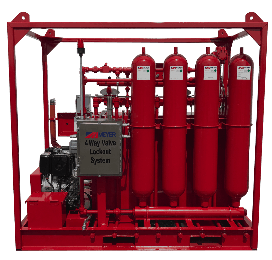

Drilling Well Control and Testing Equipment

MEYER engineers and manufactures rugged, reliable, and smart solutions for well control testing equipment and oil and gas control systems. We are API-16D licensed and headquartered in the United States, with several service locations within close proximity to international ports. Our strategic placement of service locations allows us to provide responsive service to both domestic and international drilling operations, workover, and frac rental companies.

With all of our well testing equipment and oilfield control systems meeting API standards, MEYER is able to provide unmatched service, with the ability to meet and exceed all of your control systems and well testing requirements. Additionally, our oil and gas well control testing equipment can safely operate in all high-risk environments working with high pressure, high temperature, and high concentrations of H2S (also known as sour gas).

MEYER’s well control testing equipment and oil and gas control systems are used by many of the world’s leading companies. Our successful track record of providing high-quality oilfield equipment and field services instills trust in every client we work with because at MEYER, improving safety, increasing productivity, and eliminating expensive delays and repairs are our top priorities when engineering our oil and gas control systems and well control testing equipment.

Offering Short and Long Term Rentals

MEYER has over 300 pieces of rental equipment in their fleet from Accumulators, Grease Units, SPYDER™ Manifolds, Test Units and more. Call us today to see what’s available!